At the intersection of marine engineering and environmental conservation, we explore how propeller cavitation and hull design impact underwater noise pollution.

Underwater noise from commercial vessels can reach up to 190 decibels—louder than a jet engine at take-off—disrupting marine ecosystems across vast ocean areas.

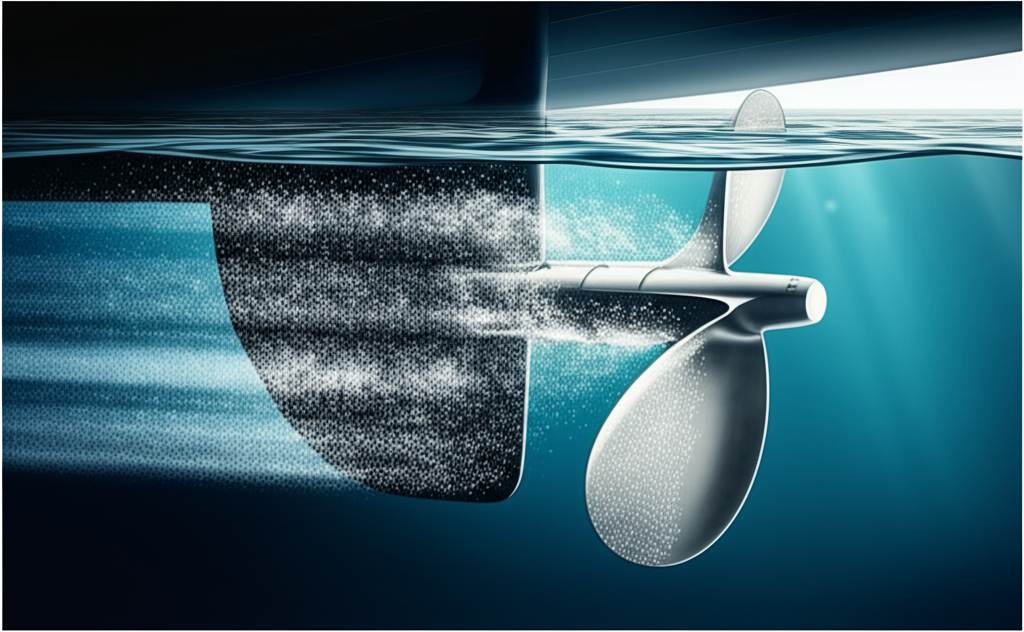

Understanding propreller cavitation

Bubble Formation

Violent Collapse

Acoustic Impact

Hull design & noise generation

A ship’s hull form determines how water flows around the vessel, influencing the volume and frequency of underwater noise generated.

Hydrodynamic Flow

Turbulent Flow

Acoustic Emissions

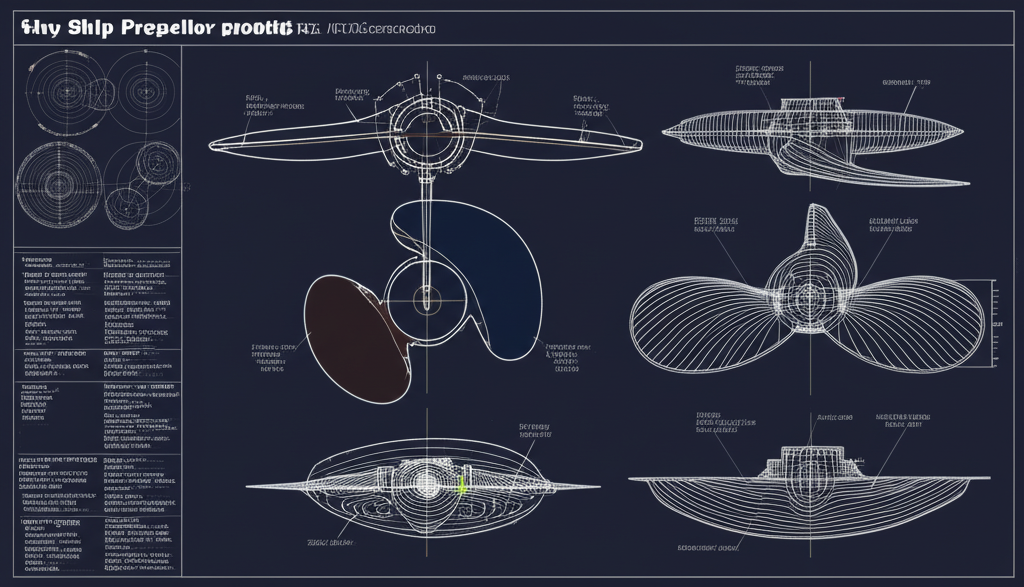

Engineering Solutions to Reduce Noise

Blade Shape Optimization

Tip Modifications

Blade Skewing

Specialized Coatings

Environmental Impact of Underwater Noise

Beyond the depths of 200 meters where light is limited, the ocean is essentially an acoustic world. Marine species depend on sound for vital functions.

Disruption of Marine Communication

Long-term Ecological Consequences

International Guidelines & Regulations

2004

2004

Present

Case Studies in Noise Mitigation

North Atlantic Research Vessel - 158dB Reduction

- Structural modifications to engine mounts reduced vibration transfer to the hull

- Application of specialized noise-dampening coatings to 85% of the hull surface

- Propeller redesign with optimized blade skewing and tip modifications

Baltic Sea Ferry Retrofit - 12dB Reduction

- Installation of low-noise propellers with optimized blade design

- Application of vibration-dampening coatings to critical hull sections

- Implementation of operational speed guidelines in sensitive areas

Sinay's Innovative Acoustic Solutions

AI-Powered PAM System

Real-Time Monitoring

Cloud-Based Analysis

- Industrial Operators Looking To Minimize Ecological Impact

- Research Institutions Studying Marine Biodiversity

- Conservation Agencies Monitoring Protected Species

- Port Authorities Managing Underwater Noise

- Government Bodies Enforcing Environmental Regulations

PROTECTING OUR OCEANS

With ongoing innovation in hardware and software, we continue to shape the future of sustainable ocean operations, biodiversity research, and environmental policy.

FAQ

Ship noise can travel remarkable distances underwater—up to 100 miles or more in ideal conditions. Sound travels nearly four times faster in water than in air, and low-frequency sounds from large vessels can propagate across entire ocean basins under certain conditions.

When properly implemented, noise reduction technologies often improve vessel performance. Optimized propeller designs and hull forms that reduce noise typically also reduce fuel consumption by improving hydrodynamic efficiency. The initial investment in noise reduction technology can result in operational cost savings over time.

Currently, most underwater noise regulations are voluntary guidelines rather than mandatory requirements. However, this is changing rapidly. The EU’s Marine Strategy Framework Directive requires member states to address underwater noise, and several countries are developing mandatory standards. The IMO continues to work on international guidelines that may become mandatory in the future.

Implementation costs vary widely depending on vessel type, size, and the specific technologies adopted. For new builds, incorporating noise reduction from the design phase typically adds 3-8% to construction costs. Retrofitting existing vessels is more expensive, with costs ranging from $500,000 for basic modifications to several million dollars for comprehensive solutions on large vessels.

Marine mammals, particularly whales and dolphins, are most severely affected due to their reliance on sound for communication, navigation, and finding food. However, research shows that fish, invertebrates, and even zooplankton are impacted by anthropogenic noise. Species that communicate in the same frequency ranges as vessel noise (typically 5-400 Hz) experience the greatest disruption.

Underwater noise is measured using hydrophones—specialized underwater microphones that detect acoustic pressure. Modern monitoring systems use arrays of hydrophones connected to data processing systems that analyze sound levels, frequencies, and sources. Advanced systems like Sinay’s PAM platform use AI to identify specific noise sources and marine species in real-time.