The offshore industry involves complex procedures that require significant coordination and resources. Adverse weather, including high winds, storms, and waves, can significantly impact offshore projects, leading to downtime and hazards for workers and equipment.

Proper planning is critical in offshore projects to mitigate risks, allocate resources efficiently, and complete tasks on time. To develop a contingency plan to address weather-related disruptions, well-prepared plans must consider all potential scenarios, including bad weather, planned and unplanned maintenance, and costs.

Marine contractors can take measures to avoid downtime due to bad weather. Weather monitoring tools providing metocean information are essential in reducing weather downtime and increasing the efficiency of offshore projects.

The price of bad weather: balancing safety and production in offshore operations

Various adverse weather conditions, including high winds, storms, and waves, can impact offshore operations. These weather conditions can lead to significant downtime hence costs, as operators may be forced to halt operations and maintenance to ensure the safety of workers and equipment.

High winds, for example, can make it challenging to operate cranes, while storms and heavy rain can create a hazardous work setting for crew members. Waves can also cause damage to equipment and infrastructure, such as offshore platforms and pipelines, leading to lengthy and costly repairs.

The loss of Seacor power and 13 from 19 crewmembers onboard on April 13th, 2021, came as a terrifying reminder that the elements of nature must be respected and a better plan should be in place since the investigation afterward unveiled errors in the weather forecasting processes in place.

The High Cost of Bad Weather

In addition to the dangers posed to workers, inclement weather can have a significant financial impact on offshore operations. Downtime due to bad weather can lead to delays in production, resulting in lost revenue for operators and the accumulation of very high costs. In some cases, operators may also be required to pay penalties for failing to meet production targets.

The downtime costs due to bad weather can be high, and operators must be prepared to manage these risks. This includes investing in weather monitoring and forecasting tools to predict potential downtime and maintaining equipment and infrastructure to withstand adverse weather.

It’s also essential for operators to have an emergency response plan in place to address weather-related issues. This may include having trained personnel and emergency response teams on standby to address any hazards and having a contingency plan to minimize weather-related downtime’s impact on operations.

Overall, downtime due to bad weather is a significant risk for offshore projects. However, with proper planning and investment in preventative and mitigation measures, operators can minimize the impact of adverse weather on their operations and ensure the safety of their workers and equipment.

Navigating the unpredictable: the role of planning in offshore operations

Effective planning is critical in offshore projects as they often involve complex tasks requiring significant coordination and resources. In addition, the offshore environment can be unpredictable and challenging due to extreme weather, sea currents, and equipment limitations. By planning each operation in detail, marine contractors can allocate resources efficiently to minimize costs, complete tasks on time, and mitigate risks.

In every phase of a project, it is imperative to perform a risk assessment that helps us improve in the following key areas:

- Processes

- Hazard identification

- Proper use of resources

- Rules and regulations compliance

Inclement weather can significantly complicate offshore operations, making planning even more crucial. Strong winds, high waves, and heavy rain can affect the safety of personnel and equipment, making it difficult to carry out maintenance and other jobs. For example, transportation of personnel and equipment can become dangerous, leading to delays and high potential costs.

Harsh weather can also increase the risk of accidents such as slips, trips, and falls. They can also cause damage to equipment and structures, leading to costly repairs or replacements. Therefore, offshore projects must consider weather forecasts and develop contingency plans to address potential weather-related disruptions.

Planning for offshore projects involves considering all the details and potential scenarios. Therefore, marine contractors using technology must develop a comprehensive plan that considers the resources needed, timelines, and potential risks. By doing so, they can identify potential challenges and opportunities for improvement.

In summary, planning each phase in an offshore project is crucial to ensure the efficient allocation of resources, timely completion of tasks, and risk mitigation. The offshore environment is unpredictable, and bad weather can complicate operations, making planning even more critical. By considering potential challenges and developing a contingency plan, marine contractors can ensure that offshore operations are carried out safely and efficiently.

Metocean Data: the key to informed decision making for offshore projects

We are in the very beginning of witnessing the effects of climate change on our planet, with a consensus among scientists that the four factors below can increase the vulnerability of offshore infrastructure:

- Temperature

- Precipitation and Flood

- Extreme Storm Events

- Sea Level Rise

Even though decarbonization initiatives are in place, it is only natural to expect an increase in those phenomena in the near future.

Weather monitoring tools are essential in reducing weather downtime in offshore projects. These tools help marine contractors track and forecast weather changes that could cause disruptions or delays to offshore projects.

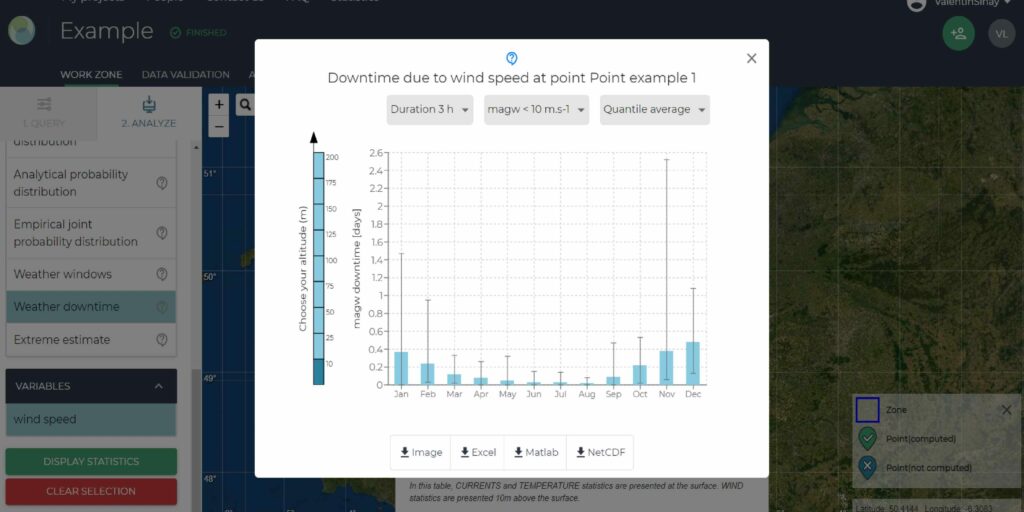

With access to metocean data, project teams can make informed decisions in every phase, from site planning to operations, like when to deploy offshore teams and equipment and when to suspend jobs due to adverse weather, reducing downtime and increasing the efficiency of offshore projects.

The accurate and reliable monitoring of metocean data is crucial. The collection of metocean information is done using buoys, remote sensing devices, and other technologies. The info collected includes parameters such as wave height, sea surface temperature, and wind speed and direction. By analyzing the collected datasets, our oceanographers can assist you in making informed decisions using the metocean analytics solution.

Weather DownTime Cover

Insurers, to mitigate some of the risks arising from the harsh offshore environment, have introduced Weather DownTime cover, asking their clients to define the weather variables and extreme weather values which, based upon the premium, will be set, creating another essential use-case of having accurate metocean insights at your disposal.

Cost of downtime in offshore wind farms.

How to mitigate the impact and save millions.

In the unwelcoming offshore environment, unplanned downtime can happen for many reasons. Even a tiny percentage of annual downtime can quickly amount to millions of euros lost. For example, according to the wind energy in Europe 2019 report, a 3% annual downtime on a 3GW wind farm can cost 11 MM euros.

Operators can take measures to avoid downtime. For example, one effective mitigation measure is to have backup power sources like generators or battery backup systems to ensure critical equipment and systems continue operating during a power outage. This can minimize downtime and prevent damage to equipment and infrastructure.

Another important measure is to have redundant systems, which means having duplicate equipment or systems that can take over in case of failure or outage. This can minimize downtime and prevent costly repairs or replacements.

Additionally, preventive maintenance is critical and can tremendously reduce unplanned downtime. Sensors technology and artificial intelligence will play a huge role in enabling preventative maintenance by analyzing the health status of essential equipment in real-time and alarming identifying patterns well in advance of human operators.

Finally, the human factor remains extremely important as many incidents that lead to downtime are caused by human error; hence continuous training improvement in processes and proper work rest ratios can save millions.

Conclusion

Offshore projects are vulnerable to adverse weather conditions, leading to significant downtime and dangerous situations for workers. Proper planning and investment in preventative and mitigation measures, such as weather monitoring tools and backup systems, can help operators minimize the impact of bad weather on their operations. With the increasing effects of climate change, it is essential to consider the potential risks and develop a contingency plan to ensure the viability and efficiency of offshore projects.

Frequently Asked Questions About Weather Downtime

Offshore operations are highly susceptible to the impact of bad weather, which can cause significant delays and disruptions to project schedules. High winds, rough seas, heavy rain, and fog can all make it impossible to perform certain tasks, such as lifting heavy equipment or transferring personnel to and from offshore platforms.

In addition, bad weather can damage equipment and infrastructure, leading to costly repairs and downtime.

Bad weather-related downtime can have significant financial implications for offshore operators.

It can result in lost production and revenue, as well as increased costs for repairs and maintenance.

Additionally, delays in project schedules can result in contractual penalties and loss of future business opportunities.

Marine contractors can prepare for and mitigate the risks of bad weather-related disruptions by developing a comprehensive weather monitoring and forecasting systems, implementing effective communication protocols, and establishing contingency plans for different scenarios.

This can involve ensuring that all personnel are aware of weather-related risks and have access to appropriate safety equipment, as well as developing procedures for securing equipment and structures in the event of severe weather.

Planning plays a critical role in minimizing the impact of bad weather on offshore operations.

Effective planning involves identifying potential weather-related risks, developing contingency plans for different scenarios, and establishing communication protocols for alerting personnel to potential hazards.

Planning also involves ensuring that equipment and infrastructure are designed and maintained to withstand the weather conditions that are common in the region.

Metocean data refers to information on the physical conditions of the marine environment, such as waves, currents, tides, and wind.

This data can be collected through a variety of methods, including satellite imagery, buoys, and sensors on offshore platforms.

By analyzing metocean data, offshore operators can gain a better understanding of the environmental conditions in the region and make informed decisions about project planning, design, and operation. This can help to reduce downtime by enabling operators to anticipate weather-related risks and take appropriate measures to mitigate them.

Focus on data to make effective decisions

Discover our modules

Environmental Monitoring

Monitor air quality in real-time, be alerted when a threshold is reached & easily comply with regulation thanks to the automated reports.

Monitor water quality in real-time, predict and avoid water pollution & comply with regulations thanks to the automated reports.

Deliver a preliminary metocean analysis and the associated report in jut a few minutes.

You may also be interested by those others environment application :